Round nose end mills with four flutes are a common cutter used for machining tasks.

Short Description:

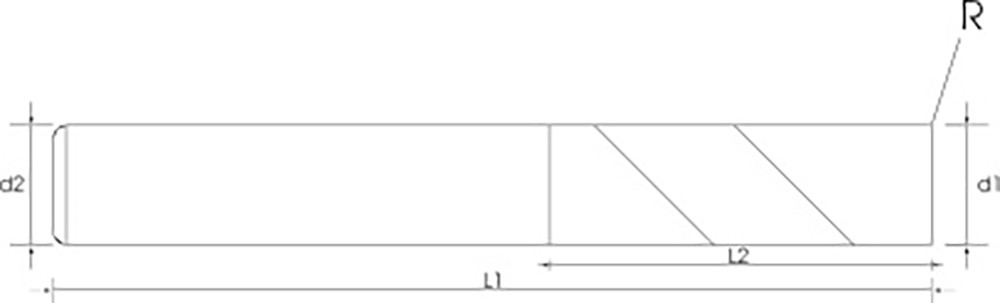

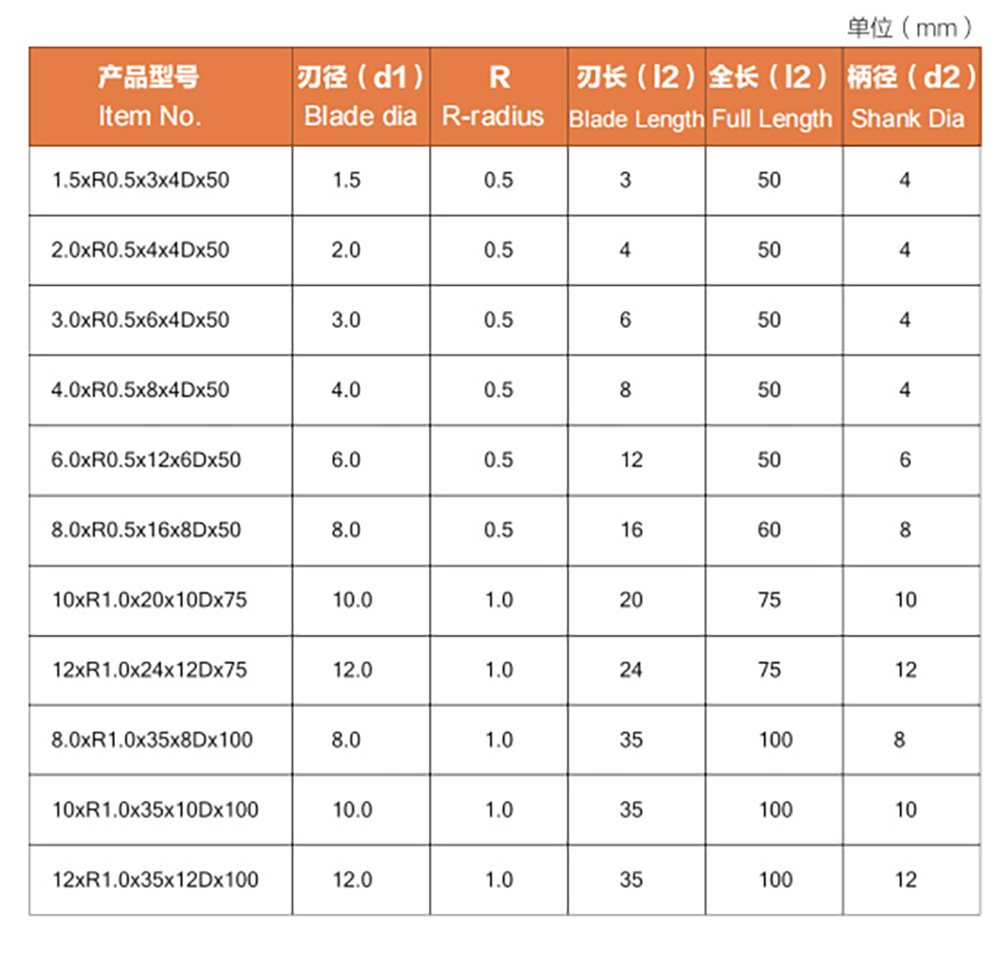

Round nose end mills with four flutes are a common cutter used for machining tasks. The following is a detailed description of the technical introduction and advantages of the four-flute round nose end mill: Insert Geometry: The four-edged insert geometry of the round nose end mill is unique. The tip of the insert is rounded to allow it to produce a smooth cutting surface during cutting. This design can be used to machine curved surfaces and is especially useful in 3D machining and engraving tasks. Insert material: The four-edge inserts of round nose end mills are usually made of high-speed steel, carbide or cubic boron nitride. These materials have excellent hardness and wear resistance, which can prolong the service life of knives. Edge Design: The four-edge edge design of the round nose end mill provides excellent cutting performance. The cutting edge is usually designed with positive edge angle and edge chamfer, which helps to reduce cutting force and vibration and improve cutting efficiency. In addition, the precision of the cutting edge is high, which can provide higher machining accuracy and surface quality. Choice of the number of flutes: The four flutes of the round nose end mill provide four options for the number of flutes. The choice of the number of flutes depends on the specific machining needs and workpiece material. Typically, more flutes provide higher cutting efficiency and smoother machined surfaces. However, too many flutes may increase cutting forces and affect tool stability. Application fields: Round nose end mill with four edges is suitable for cutting various metal materials, including cast iron, steel, stainless steel, aluminum alloy, etc. Its unique blade geometry and edge design make it excellent on curved surfaces and engraving. Advantages: Round nose end mills with four flutes offer several advantages. First, the rounded nose design of the insert enables it to produce a smooth cutting surface, improving the quality of the machined surface. Secondly, the choice of blade material and number of edges can be adjusted according to specific processing requirements to achieve higher production efficiency and processing accuracy. In addition, the round nose end mill with four flutes can reduce burrs and residual marks and provide a smoother machined surface. To sum up, the four-flute round nose end mill has the advantages of unique geometry, insert material, cutting edge design and number of flutes. It is suitable for cutting a variety of materials, especially in curved surfaces and engraving. Its excellent cutting performance and excellent machined surface quality make it one of the indispensable tools in cutting.