In recent years, with the development of intelligent manufacturing, CNC tools, as advanced manufacturing tools, are increasingly widely used. Its efficiency, precision and flexibility have brought revolutionary changes to the manufacturing industry and greatly improved production efficiency and product quality. Let’s take a detailed look at the application and development of CNC tools.

CNC tools refer to tools that control the cutting process through CNC technology. They are operated by a computer control system and can realize automated and integrated cutting processes. Compared with traditional tools, CNC tools have the following advantages:

First of all, CNC tools are efficient and energy-saving. Traditional tools have a large loss during the cutting process, while CNC tools can minimize energy consumption and material waste through precise parameter setting and processing path planning, and achieve the goal of high efficiency and energy saving.

Secondly, CNC tools have precise processing capabilities. The CNC system can accurately control the movement trajectory, rotation speed, feed speed and other parameters of the tool according to the preset process requirements to ensure the accuracy and quality of the processing process and reduce the impact of human factors on the processing results.

Thirdly, CNC tools have flexible production capabilities. Traditional tools need to be replaced when processing workpieces of different shapes, while CNC tools can automatically adjust the position and angle of the tool according to program settings to achieve multi-functional processing, significantly improving production efficiency and flexibility.

It is worth mentioning that CNC tools are increasingly used in the field of intelligent manufacturing. By linking with other intelligent equipment (such as robots, sensors, etc.), CNC tools can realize functions such as automated production, full-process monitoring, and data analysis, providing enterprises with more intelligent solutions.

In recent years, the Chinese government has continuously increased its support for intelligent manufacturing, and the CNC tool industry has also achieved rapid development. At present, domestic CNC tool brands are constantly emerging, and competition is becoming increasingly fierce. According to industry experts’ predictions, the CNC tool market will maintain a high growth rate in the future, and the market size is expected to continue to expand.

However, the development of the CNC tool market still faces some challenges. On the one hand, technology updates rapidly, and companies need to continuously learn and master new technologies to improve the intelligence level of cutting tools; on the other hand, market demands are diversified, and customized cutting tool solutions must be provided according to the needs of different industries.

Generally speaking, CNC cutting tools, as a powerful tool in the era of intelligent manufacturing, have broad market prospects and development space. In the future, with the continuous development of digital, networked and intelligent technologies, CNC cutting tools will play an important role in promoting the transformation and upgrading of the manufacturing industry and promote the high-quality development of my country’s manufacturing industry.

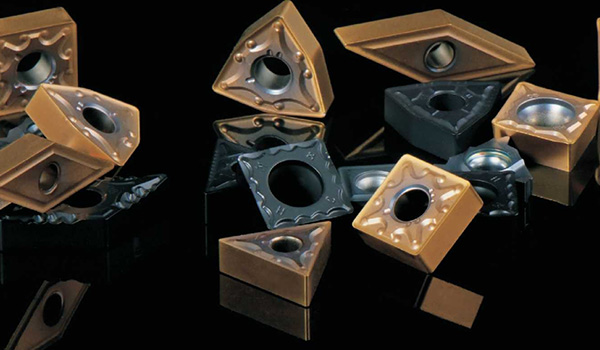

Taizhou Xiangrong Precision Technology Co., Ltd. Located in the Zhejiang Huangyan Mold Smart Town, known as the hometown of molds, the national sales and service center is located in Zhejiang Huangyan Mold Expo City, connected to Ningbo to the north, Wenzhou to the south, 207 kilometers away from Hangzhou, and located in the center of Zhejiang’s coastal industrial economic belt. , the company mainly produces and manufactures domestic high-end steel casting CNC blades, stainless steel CNC blades, titanium alloy CNC blades, high temperature alloys, steel casting CNC turning blades, stainless steel CNC turning blades, titanium alloy CNC turning blades and other cost-effective cutting tools.

The company is committed to the research and development of CNC tools for difficult-to-machine materials such as high-hard materials, stainless steel materials, titanium alloy materials, and high-temperature alloy materials, providing enterprises with high-quality tool solutions and helping them solve practical problems!

Post time: Sep-22-2023