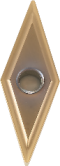

VNMG160404 Turning Insert

Short Description:

VNMG160404, VNMG060408 and VNMG160412 are three turning inserts with unique design and performance. The following is a technical introduction and comparison of them: VNMG160404: This blade has a VNMG design and the blade measures 16mm x 16mm with a 4.76mm tip diameter. It uses a high-hardness tool material to provide excellent wear resistance and cutting performance. The tool geometry is precisely calculated and optimized to ensure insert stability and cutting efficiency. VNMG160404 is suitable for general precision cutting and fine machining, especially for the machining of steel, stainless steel and cast iron materials. VNMG060408: This blade measures 6mm x 6mm with a 4.76mm tip diameter. Compared with VNMG160404, VNMG060408 has a shorter but wider cutting edge, which is suitable for fine cutting and medium duty machining. Its cutting edge design can provide better cutting stability and machining efficiency. VNMG060408 is also suitable for machining common metal materials such as steel, stainless steel and cast iron. VNMG160412: This blade measures 16mm x 16mm with a 4.76mm tip diameter. Compared with VNMG160404, VNMG160412 has a longer cutting edge, which is suitable for heavier cutting and high load machining. It is manufactured with high hardness materials and has a special blade design to provide higher tool life and machining accuracy. VNMG160412 is suitable for metal materials that require high cutting load, such as alloy steel, stainless steel, high-strength steel, etc. All three inserts feature advanced coating technology for better cutting performance and tool life. Coatings reduce cutting friction and heat buildup, resulting in lower insert wear and cutting forces. In addition, their tool geometry and edge design have been optimized to increase cutting efficiency and machining quality. In contrast, VNMG160404 is suitable for general precision cutting and fine machining, VNMG060408 is suitable for medium load and fine cutting, and VNMG160412 is suitable for heavy cutting and high load processing. When selecting, the user should determine the most suitable blade model according to the material, cutting requirements and processing load. Overall, all three inserts provide superior cutting performance and results, making metalcutting more efficient and precise.